Portable Flange Machining Tool for Oil and Gas Pipelines

# Portable Flange Machining Tool for Oil and Gas Pipelines

## Introduction to Portable Flange Machining Tools

The oil and gas industry relies heavily on pipelines to transport valuable resources across vast distances. Maintaining these pipelines requires specialized equipment, and one of the most critical tools in this maintenance arsenal is the portable flange machining tool. These innovative devices have revolutionized how we approach pipeline maintenance and repair operations.

## What is a Portable Flange Machining Tool?

A portable flange machining tool is a compact, mobile device designed to perform precision machining operations on pipeline flanges in the field. Unlike traditional machining methods that require removing flanges and transporting them to workshops, these portable tools bring the workshop to the job site.

### Key Features of Modern Portable Flange Machines:

– Compact and lightweight design for easy transportation

– High-precision machining capabilities

– Versatile operation for various flange sizes and types

– Robust construction for harsh field conditions

– User-friendly interfaces for efficient operation

## Applications in Oil and Gas Pipelines

Portable flange machining tools serve numerous critical functions in pipeline maintenance:

### 1. Flange Facing Operations

These tools can precisely machine flange faces to restore proper sealing surfaces, eliminating leaks and ensuring pipeline integrity.

### 2. On-Site Repairs

When pipeline flanges become damaged during operation or installation, portable machining tools allow for immediate repairs without costly shutdowns or component replacement.

### 3. Preventive Maintenance

Regular maintenance using portable flange machines helps prevent future failures by addressing minor issues before they escalate.

## Advantages Over Traditional Methods

The adoption of portable flange machining tools offers significant benefits:

– Reduced downtime – repairs can be performed without removing pipeline sections

– Cost savings – eliminates transportation costs and reduces labor requirements

– Improved safety – minimizes risks associated with component removal and transport

– Enhanced precision – specialized tools provide better results than manual methods

– Increased efficiency – faster turnaround times for maintenance operations

## Choosing the Right Portable Flange Machining Tool

When selecting a portable flange machining tool for oil and gas pipeline applications, consider these factors:

### 1. Compatibility

Ensure the tool can handle the range of flange sizes and types common in your operations.

### 2. Power Requirements

Evaluate whether electric, hydraulic, or pneumatic power sources best suit your field conditions.

### 3. Precision Capabilities

Look for tools with micron-level precision to meet industry standards for pipeline integrity.

### 4. Durability

Choose models built to withstand the harsh environments typical of oil and gas operations.

## Future Trends in Portable Flange Machining

The industry continues to see advancements in portable flange machining technology:

– Integration with digital measurement systems for real-time quality control

– Development of lighter yet more powerful models

– Improved automation features for increased efficiency

– Enhanced connectivity for remote monitoring and data collection

## Conclusion

Portable flange machining tools have become indispensable in the oil and gas industry, offering a practical solution for maintaining pipeline integrity while minimizing operational disruptions. As technology advances, these tools will continue to play a vital role in ensuring the safe and efficient transportation of energy resources worldwide.

You May Also Like

トレーラーハウスで叶える自由なライフスタイル

March 17, 2025

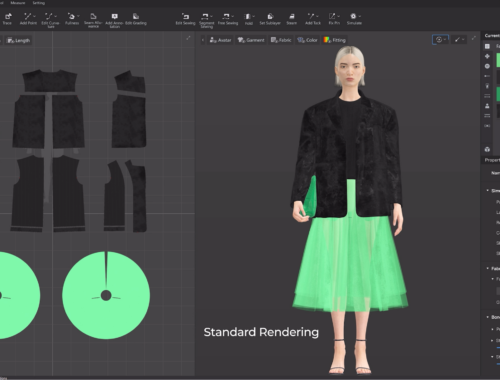

The Future of Fashion: How Artificial Intelligence is Revolutionizing the Industry

February 28, 2025