Portable Flange Machining Tool for Oil and Gas Pipelines

# Portable Flange Machining Tool for Oil and Gas Pipelines

## Introduction

The oil and gas industry relies heavily on pipelines to transport resources efficiently. Maintaining these pipelines requires specialized tools, and one of the most critical is the portable flange machining tool. This innovative equipment allows for on-site repairs and modifications, reducing downtime and improving operational efficiency.

## What is a Portable Flange Machining Tool?

A portable flange machining tool is a compact, mobile device designed to machine, repair, and maintain flanges on oil and gas pipelines without the need to remove the pipeline from service. These tools are engineered to perform various operations, including:

– Facing

– Drilling

– Boring

– Counterboring

– Grooving

## Key Features of Portable Flange Machining Tools

Modern portable flange machining tools come with several advanced features that make them indispensable in the field:

– Lightweight and Compact Design: Easy to transport and set up in confined spaces.

– High Precision: Ensures accurate machining to meet industry standards.

– Versatility: Compatible with various flange sizes and types.

– Durability: Built to withstand harsh environmental conditions.

– Automated Functions: Some models offer CNC capabilities for enhanced precision.

## Benefits of Using Portable Flange Machining Tools

The use of portable flange machining tools offers numerous advantages for oil and gas pipeline maintenance:

– Reduced Downtime: On-site machining eliminates the need to disassemble and transport pipeline sections.

– Cost-Effective: Minimizes labor and transportation costs associated with traditional methods.

– Improved Safety: Reduces risks associated with pipeline disassembly and reassembly.

– Enhanced Efficiency: Quick setup and operation lead to faster project completion.

– Environmental Benefits: Less disruption to surrounding areas compared to traditional methods.

## Applications in the Oil and Gas Industry

Portable flange machining tools are used in various scenarios within the oil and gas sector:

– Pipeline Construction: Ensuring proper flange alignment and sealing during installation.

– Maintenance and Repair: Addressing wear and tear or damage to existing flanges.

– Emergency Repairs: Quick response to leaks or failures in critical pipeline sections.

– Retrofitting: Upgrading older pipelines to meet current standards.

## Choosing the Right Portable Flange Machining Tool

Selecting the appropriate tool for your needs involves considering several factors:

– Flange Size and Type: Ensure compatibility with the flanges you work with.

– Power Source: Options include electric, hydraulic, or pneumatic systems.

– Portability: Weight and size should match your operational requirements.

– Precision Requirements: Higher precision tools may be necessary for critical applications.

– Budget: Balance cost with the features and durability you need.

## Conclusion

Portable flange machining tools are revolutionizing the way oil and gas pipelines are maintained and repaired. Their ability to perform precise machining on-site saves time, reduces costs, and enhances safety. As technology advances, these tools will continue to play a vital role in ensuring the reliability and efficiency of pipeline systems worldwide.

You May Also Like

Monkey Mart: A Primate Paradise for Shoppers

March 20, 2025

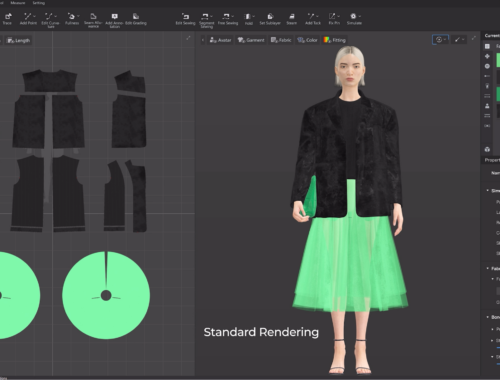

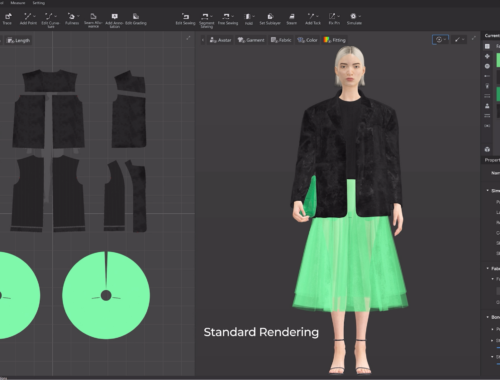

The Future of Fashion: How Artificial Intelligence is Revolutionizing the Industry

February 28, 2025