On-Site Flange Machining: Precision Solutions for Industrial Applications

# On-Site Flange Machining: Precision Solutions for Industrial Applications

## Introduction to On-Site Flange Machining

On-site flange machining has become an essential service for industries that require precision maintenance and repair without the need for equipment disassembly. This specialized process allows for the machining of flanges directly at the installation site, saving time and reducing downtime for critical operations.

## The Importance of Flange Machining in Industrial Settings

Flanges play a crucial role in piping systems, pressure vessels, and other industrial equipment. Properly machined flanges ensure:

– Leak-proof connections

– Proper alignment of connected components

– Long-term system reliability

– Compliance with industry standards

## Advantages of On-Site Flange Machining

Choosing on-site flange machining over traditional workshop methods offers numerous benefits:

### Reduced Downtime

By performing machining operations directly at the installation site, companies can avoid the lengthy process of disassembling and transporting components to a workshop.

### Cost Savings

On-site services eliminate:

– Transportation costs

– Extended production stoppages

– Potential damage during disassembly/reassembly

### Precision Results

Modern portable machining tools can achieve workshop-quality results with:

– High accuracy surface finishing

– Precise dimensional control

– Custom solutions for unique situations

## Common Applications of On-Site Flange Machining

Keyword: On-site flange machining

This service is particularly valuable in:

### Oil and Gas Industry

Critical for maintaining pipeline integrity and processing equipment in remote locations.

### Power Generation

Essential for turbine connections, boiler systems, and other power plant components.

### Chemical Processing

Maintains the integrity of corrosive material containment systems.

### Water Treatment Facilities

Ensures proper sealing in large-diameter piping systems.

## The On-Site Machining Process

A typical on-site flange machining operation involves:

1. Initial inspection and measurement

2. Setup of portable machining equipment

3. Precision machining operations

4. Quality control verification

5. Final surface treatment (if required)

## Choosing the Right Service Provider

When selecting an on-site flange machining provider, consider:

– Experience with your specific industry

– Equipment capabilities and technology

– Safety record and compliance

– Response time for emergency situations

– Quality assurance processes

## Future Trends in On-Site Flange Machining

The field continues to evolve with:

– Advanced portable CNC technology

– Improved measurement and alignment systems

– Environmentally friendly machining processes

– Integration with predictive maintenance programs

On-site flange machining represents a smart solution for industries that value efficiency, precision, and minimal disruption to operations. As technology advances, these services will become even more precise and accessible for a wider range of industrial applications.

You May Also Like

HOW TO PREVENT MOLD AND MILDEW ON TRUCK TARPAULINS?

November 22, 2024

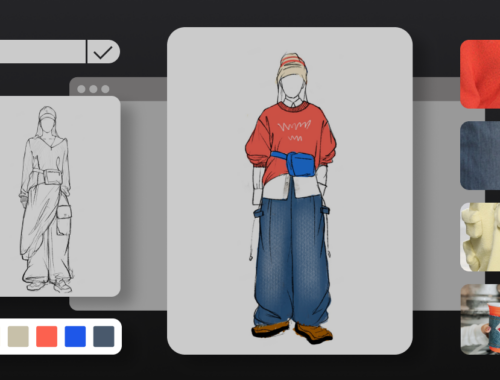

The Future of Fashion: How Artificial Intelligence is Revolutionizing the Industry

February 28, 2025