How rapid prototyping benefits product development

For product designers and developers, rapid prototyping can play a crucial role in bringing a commodity from concept to finished product. Thanks to new technologies like CNC machining and 3D printing, developers can iterate prototypes in a short time period, trying out new designs and materials.

Rapid prototyping is the process of assembling functional or non-functional prototypes using digital manufacturing technologies. These technologies can turn digital CAD files into physical prototypes in a short space of time, allowing businesses to create prototypes quickly, and cost less than one-off prototypes built using traditional techniques.

This article looks at how rapid prototyping improves product development, saving businesses time and money, and delivering a better final product.

Iterate multiple versions

Rapid prototyping is ideal for product developers who need to test and assess different versions of their product in order to establish the right course of action.

CAD software allows designers to make simple tweaks to their design and create multiple iterations. For example, Version 1.0 of an electronics housing might contain threads for screws, while Version 2.0 might contain a snap-close latch.

Because rapid prototyping technologies do not use expensive tooling, the designer can easily prototype both versions of their design in order to test both.

Diverse iteration gives businesses more flexibility, allowing them to explore multiple pathways on the route to launching their product.

Test multiple materials

A related advantage of rapid prototyping in product development is the ability to test multiple materials. Using the same CAD file, a manufacturer can create multiple copies of a product in different materials (or simply multiple colors) with minimal effort.

This is incredibly useful during product development, because it allows developers to carry out physical testing on versions of their product made from different materials.

During this testing phase, it may transpire that, for example, a certain plastic is too brittle for the product’s end purpose, or that a certain conductive metal gets too hot to touch when the product’s motor is running.

Of course, product designers can predict how certain materials will perform without actually obtaining those materials, but testing a physical prototype provides more concrete results.

Shorten time to market

The clue is in the name: rapid prototyping allows businesses to develop prototypes extremely quickly, which can significantly reduce the total time required to bring a product to market.

When a prototyping service provider receives a CAD file, they can begin manufacturing almost immediately — provided there are no manufacturability issues with the design. This means businesses can sometimes acquire their prototypes in a matter of days.

Cheaper methods

Rapid prototyping comprises a handful of manufacturing processes, some of which have very little in common: CNC machining is a subtractive process, while 3D printing is an additive process, and the two technologies work in very different ways.

That being said, both CNC and AM represent affordable means of prototyping, since they both have very low startup costs. Neither process requires tooling, which makes it possible to order small quantities of parts without paying a premium.

It is possible to create rapid prototypes using molding techniques — using a rapid tooling process, for example. However, many businesses favor 3D printing or CNC machining for one-off prototypes or very small orders.

Correction of flaws

Rapid prototyping can be highly valuable during product development, because it allows developers to identify flaws in a design that may not be apparent during the early design phase.

In an ideal world, your newly built prototype will work perfectly. However, building a prototype then noticing it flaws is much better than missing those flaws altogether. A flawed prototype means you can simply rework the design and build a new prototype; a flawed final product, however, is a catastrophe with no easy fix.

Better still, prototyping companies like 3ERP will use their expertise to analyze your CAD design, and if there’s an obvious problem with it, we’ll tell you as soon as we can.

Present ideas to management

One of the main goals of prototyping is to create a physical object that can be demonstrated to important people. Prototypes are great for investor pitches, for example. (Though that’s beyond the realm of product development.)

While you’re still developing a product, prototypes can be a great way to communicate with management or other areas of your business. Let’s say you’ve got a budget meeting on the horizon, then you might need to present your prototype to ensure you get the funding you need.

You might also use a prototype to show your product to your marketing department, allowing them to work on promotional materials for your product.

Rapid prototyping helps to speed this kind of in-house business along.

Risk mitigation

One of the key advantages of rapid prototyping is risk mitigation. By prototyping as much as possible as quickly as possible, it becomes easier to identify problems in a product.

Products that have been extensively prototyped — and therefore extensively tested — pose less risk than products that have been minimally prototyped or not prototyped at all.

Read our 5 tips for creating professional prototypes, or request a quote from 3ERP today.

Share this blog:

Keyword: cnc milling

You May Also Like

Essential Pool Supplies for a Perfect Swimming Experience

March 18, 2025

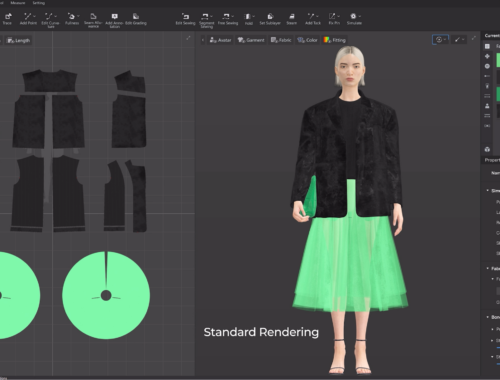

AI in Fashion: Revolutionizing Design, Shopping, and Supply Chains

February 28, 2025