Flange Facing Machine: Essential Equipment for Precision Machining

html

Flange Facing Machine: Essential Equipment for Precision Machining

In the world of industrial machining, precision is paramount. One of the key pieces of equipment that ensures this precision is the flange facing machine. Designed to create smooth, flat surfaces on flanges, these machines play a critical role in ensuring proper sealing and alignment in piping systems, pressure vessels, and other industrial applications.

What is a Flange Facing Machine?

A flange facing machine is a specialized tool used to machine the face of a flange to achieve a smooth, flat surface. This process is essential for creating a tight seal between flanges, which is crucial in high-pressure and high-temperature applications. These machines are portable, allowing them to be used on-site, eliminating the need to remove flanges for machining.

Key Features of Flange Facing Machines

Modern flange facing machines come equipped with several advanced features that enhance their performance and efficiency:

- Portability: Designed for on-site use, reducing downtime and costs

- Precision Cutting: Capable of achieving surface finishes as fine as 3.2 μm Ra

- Versatility: Can handle various flange sizes and materials

- Automated Operation: Many models feature CNC controls for consistent results

- Durability: Built to withstand harsh industrial environments

Applications of Flange Facing Machines

Flange facing machines find applications across numerous industries:

Keyword: Flange facing machine

- Oil and gas pipelines

- Power generation plants

- Chemical processing facilities

- Shipbuilding and marine applications

- Water treatment plants

Benefits of Using Flange Facing Machines

The use of flange facing machines offers several significant advantages:

- Improved Seal Integrity: Perfectly machined surfaces ensure leak-free connections

- Cost Savings: On-site machining eliminates transportation costs and reduces downtime

- Increased Safety: Properly faced flanges reduce the risk of leaks in hazardous environments

- Extended Equipment Life: Proper flange maintenance prevents premature failure

- Versatility: Can be used for both new installations and maintenance operations

Choosing the Right Flange Facing Machine

When selecting a flange facing machine, consider the following factors:

- Flange size range requirements

- Material types to be machined

- Required surface finish quality

- Portability needs

- Available power sources

- Budget constraints

Investing in a high-quality flange facing machine can significantly improve the efficiency and reliability of your industrial operations. With proper maintenance and operation, these machines can provide years of reliable service, ensuring your flange connections remain secure and leak-free.

MPO to LC Fiber Optic Cable Overview

You May Also Like

Dino Game: A Journey Through Prehistoric Challenges

March 21, 2025

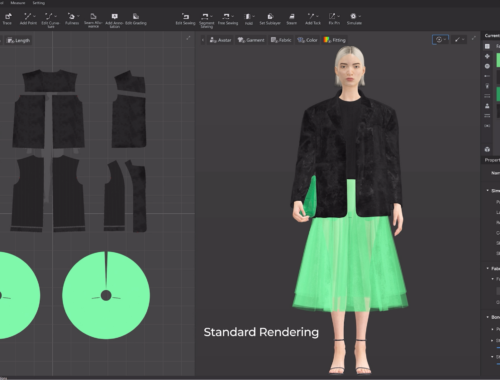

AI in Fashion: Revolutionizing Design, Shopping, and Sustainability for a Smarter Future

March 1, 2025