Chemical Plant Flange Preparation Machine for Maintenance

# Chemical Plant Flange Preparation Machine for Maintenance

## Introduction to Flange Preparation in Chemical Plants

Flange preparation is a critical process in chemical plant maintenance, ensuring proper sealing and connection of piping systems. The flange preparation machine has become an indispensable tool for maintenance teams working in these demanding environments.

## Why Specialized Equipment is Necessary

Chemical plants present unique challenges for maintenance operations:

– Corrosive environments that degrade standard tools

– Strict safety requirements for equipment used in hazardous areas

– Precision requirements for high-pressure systems

– Need for efficient operations to minimize downtime

## Key Features of Chemical Plant Flange Preparation Machines

Modern flange preparation machines designed for chemical plant maintenance typically include:

### 1. Corrosion-Resistant Construction

Machines are built with materials that withstand exposure to chemicals, often featuring:

– Stainless steel components

– Protective coatings

– Sealed electrical systems

### 2. Precision Cutting Capabilities

Accurate flange facing is crucial for proper sealing:

– Computer-controlled cutting paths

– Adjustable cutting depths

– Consistent surface finish

### 3. Portability and Adaptability

Designed for use in confined plant spaces:

– Compact designs

– Modular components

– Quick setup features

## Maintenance Benefits of Using Specialized Equipment

Implementing proper flange preparation machines leads to:

– Reduced downtime during maintenance

– Improved seal integrity

– Longer-lasting flange connections

– Safer working conditions

## Choosing the Right Machine for Your Plant

When selecting a flange preparation machine, consider:

– Pipe size range requirements

– Material compatibility

– Power source availability

– Certification requirements for your facility

## Conclusion

Investing in a high-quality flange preparation machine specifically designed for chemical plant maintenance can significantly improve operational efficiency, safety, and reliability. These specialized tools help maintenance teams meet the demanding requirements of chemical processing environments while ensuring long-term system integrity.

You May Also Like

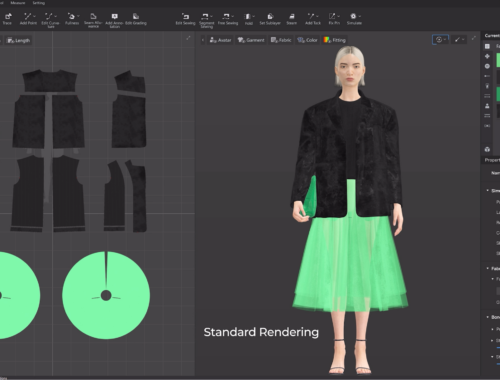

The Future of Fashion: How Artificial Intelligence is Revolutionizing the Industry

February 28, 2025

Automatic Weather Station Price Analysis and Market Trends

March 16, 2025