API 607 vs API 608: Key Differences and Applications

html

API 607 vs API 608: Key Differences and Applications

When it comes to valve testing and fire safety standards, API 607 and API 608 are two critical specifications often referenced in the oil, gas, and petrochemical industries. While both standards focus on fire-safe valves, they serve different purposes and apply to distinct types of valves. Understanding the differences between API 607 and API 608 is essential for engineers, procurement specialists, and safety professionals.

What is API 607?

API 607 is a standard developed by the American Petroleum Institute (API) that specifies the fire testing requirements for quarter-turn valves and other valves with non-metallic seats. The primary objective of API 607 is to ensure that valves can withstand fire exposure while maintaining their sealing integrity.

Key features of API 607 include:

- Applies to soft-seated quarter-turn valves (e.g., ball valves, butterfly valves)

- Requires fire testing for 30 minutes at temperatures up to 1,400°F (760°C)

- Evaluates external leakage and operability after fire exposure

- Includes both type testing and production testing requirements

What is API 608?

API 608, on the other hand, is a standard that covers the design, materials, and testing requirements for metal-seated ball valves used in pipeline and piping systems. While it includes some fire safety considerations, its scope is broader than just fire testing.

Key aspects of API 608 include:

- Focuses on metal-to-metal seated ball valves

- Includes dimensional, design, and material requirements

- Addresses pressure-temperature ratings

- Contains optional fire-safe testing requirements (based on API 607)

Main Differences Between API 607 and API 608

| Feature | API 607 | API 608 |

|---|---|---|

| Primary Focus | Fire testing of soft-seated valves | Design and manufacturing of metal-seated ball valves |

| Valve Types | Quarter-turn valves with non-metallic seats | Metal-seated ball valves |

| Testing Requirements | Mandatory fire testing | Fire testing is optional |

| Scope | Focused on fire safety performance | Comprehensive standard covering design, materials, and testing |

Applications and Industry Use

API 607 valves are typically specified in applications where fire safety is critical, such as:

Keyword: api 607 vs api 608

- Offshore platforms

- Refineries

- Chemical processing plants

- Any location with high fire risk

API 608 valves are commonly used in:

- Pipeline systems

- General process piping

- Applications requiring metal-seated ball valves

Office Product Key Activation Guide

You May Also Like

シャーシ設計の最適化手法とその応用

March 20, 2025

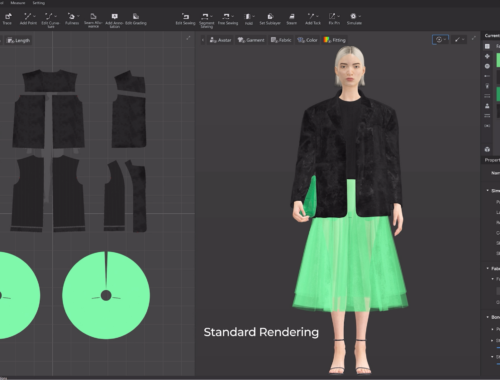

The Future of Fashion: How Artificial Intelligence is Revolutionizing the Industry

February 28, 2025