Industrial Air-Cooled Chillers for Heavy-Duty Applications

# Industrial Air-Cooled Chillers for Heavy-Duty Applications

## Introduction to Air-Cooled Industrial Chillers

Air-cooled industrial chillers are essential components in various heavy-duty applications, providing reliable cooling solutions for manufacturing processes, data centers, and industrial facilities. Unlike water-cooled systems, air-cooled chillers utilize ambient air to dissipate heat, making them more versatile and easier to install in locations where water supply may be limited.

## Key Features of Air-Cooled Industrial Chillers

Modern air-cooled industrial chillers come equipped with several advanced features designed to enhance performance and efficiency:

– Robust construction for durability in harsh industrial environments

– Energy-efficient compressors and fans

– Intelligent control systems for precise temperature regulation

– Compact designs for space-saving installations

– Low maintenance requirements compared to water-cooled alternatives

## Applications in Heavy-Duty Industries

Air-cooled chillers find extensive use across multiple industrial sectors:

### Manufacturing Sector

In plastic injection molding, metalworking, and food processing, these chillers maintain optimal temperatures for production equipment, ensuring consistent product quality and preventing overheating.

### Data Centers

For server cooling and IT infrastructure, air-cooled chillers provide reliable temperature control while minimizing water usage in sensitive electronic environments.

### Pharmaceutical Industry

Precision cooling is critical in pharmaceutical manufacturing, where air-cooled chillers help maintain strict temperature requirements for drug production and storage.

## Advantages Over Water-Cooled Systems

Air-cooled industrial chillers offer several distinct benefits:

– No need for cooling towers or water treatment systems

– Lower installation costs and simpler infrastructure requirements

– Reduced water consumption and environmental impact

– Greater flexibility in facility placement

– Easier maintenance with fewer components requiring regular service

## Selecting the Right Air-Cooled Chiller

When choosing an industrial air-cooled chiller for heavy-duty applications, consider these factors:

– Cooling capacity requirements

– Ambient temperature conditions

– Available installation space

– Energy efficiency ratings

– Noise level restrictions

– Future expansion possibilities

## Maintenance Best Practices

To ensure optimal performance and longevity of air-cooled industrial chillers:

1. Regularly clean condenser coils to maintain efficient heat transfer

2. Inspect and replace air filters as needed

Keyword: Air-Cooled Industrial Chillers

3. Monitor refrigerant levels and system pressures

4. Check electrical connections and components

5. Schedule professional servicing according to manufacturer recommendations

## Future Trends in Air-Cooled Chiller Technology

The industry continues to evolve with emerging technologies:

– Integration with IoT for remote monitoring and predictive maintenance

– Development of more eco-friendly refrigerants

– Advanced compressor technologies for improved energy efficiency

– Hybrid systems combining air and water cooling advantages

– Smart controls with AI-driven optimization algorithms

Industrial air-cooled chillers remain a vital solution for heavy-duty cooling applications across multiple industries. Their reliability, efficiency, and lower infrastructure requirements make them an attractive choice for facilities seeking robust temperature control without the complexity of water-cooled systems. As technology advances, these systems continue to improve in performance while reducing environmental impact.

传奇3:经典再现,重温热血岁月

You May Also Like

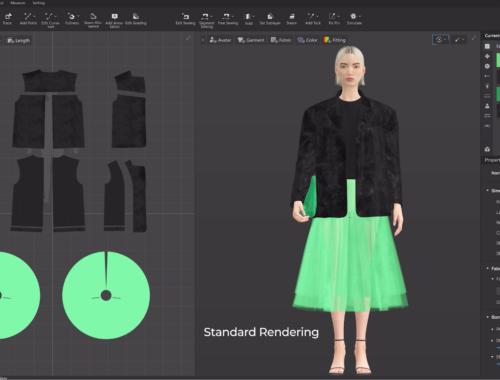

**AI in Fashion: Revolutionizing Design, Shopping, and Sustainability**

February 28, 2025

Revolutionizing Fashion: How AI is Redefining Design and Sustainability

March 1, 2025